Workplace safety decisions often look straightforward on the surface. A fan is installed, a mask is provided, a procedure is written, and the problem appears solved. Yet many safety issues persist not because people ignore risk, but because they misunderstand it.

The real difference between a safe workplace and a risky one is rarely effort; it is accuracy. Some organizations rely on experience and intuition. Others rely on measured, specialist understanding. The outcomes are very different.

Below is a practical comparison of how guidance and guesswork shape everyday safety decisions.

Identifying Hazards

Guesswork

Problems are identified after someone notices discomfort, irritation, or equipment behaving strangely. Leaders rely on memory, assumptions, or past habits from previous workplaces. Hazards are recognized only once they become visible.

Guidance

Risks are anticipated before symptoms appear. Specialists assess processes, materials, and workflows to identify exposure points early. Decisions come from analysis rather than reaction, preventing issues before staff experience them.

Evaluating Airborne Exposure

Guesswork

If a room doesn’t smell strongly or look dusty, it is assumed safe. A ventilation system is installed and rarely questioned again. Comfort becomes the measurement tool.

Guidance

Airflow patterns, capture velocity, and containment effectiveness are evaluated scientifically. Professional input, such as LEV consultancy, helps determine whether contaminants are actually removed at the source rather than diluted in the room.

Choosing Equipment

Guesswork

Organizations purchase familiar or popular equipment. If it worked elsewhere, it should work here. Selection focuses on availability and cost rather than suitability for specific processes.

Guidance

Equipment is matched to the task. The type of contaminant, its temperature, weight, and release pattern determine the correct control method. The system is designed for the process rather than adapted afterward.

Writing Procedures

Guesswork

Procedures are long and detailed because they compensate for unclear systems. Workers must remember multiple steps to stay safe, increasing the chance of human error.

Guidance

Processes are simplified. The environment and equipment do most of the protection, so procedures remain short and practical. Staff follow fewer rules because the system already prevents exposure.

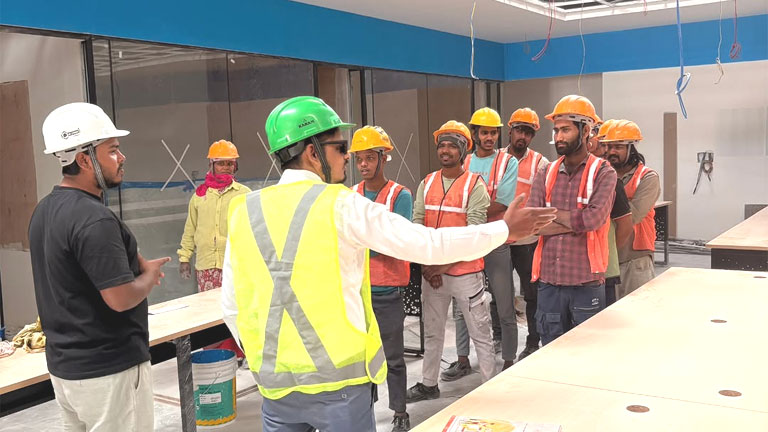

Training Employees

Guesswork

Training focuses on memorizing instructions. Workers learn what to do, but not why they do it. When conditions change, uncertainty appears.

Guidance

Training explains principles. Employees understand normal conditions and can recognize when something changes. This creates awareness rather than dependence on checklists.

Responding to Problems

Guesswork

Issues trigger quick fixes. A stronger fan, an extra mask, or a temporary adjustment is added. Each solution treats symptoms rather than causes, so problems gradually return.

Guidance

Root causes are investigated. Measurements identify the exact point of failure, allowing a permanent solution. Future incidents become less likely because the underlying process improves.

Cost Over Time

Guesswork

Initial spending is lower, but repeated adjustments accumulate. Downtime, inefficiency, and staff concerns all quietly increase operating costs.

Guidance

Upfront planning may take longer, yet fewer corrections are needed later. Stable conditions reduce interruptions and support consistent productivity.

Confidence in Daily Work

Guesswork

Workers remain cautious. They adapt behavior to compensate for uncertainty and rely on personal judgment to stay comfortable.

Guidance

People trust their environment. When systems are designed correctly, attention shifts from self-protection to performance.

The Real Difference

Guesswork reacts to problems. Guidance prevents them. Both approaches involve effort and intention, but only one produces predictable outcomes. Expert input replaces assumption with evidence, turning safety from a responsibility into a reliable feature of daily operations.

Workplace safety professionals and safety managers’ role involves continuous learning and adaptation. They are responsible for making informed decisions. Regularly reviewing safety decisions and making adjustments based on feedback can lead to better outcomes.