In today’s fast-paced world, companies need to bring ideas to market quickly. Rapid prototyping is the perfect solution for this challenge. With this post, we’ll compare and contrast various forms of rapid prototyping and help you decide which technique will work best for you. Get ready to discover the fascinating world of rapid prototyping!

What Is Rapid Prototyping?

When starting a new product development project, one of the first questions you need to answer is what type of prototype to create.

Rapid prototyping (RP) is an umbrella term that covers a range of different techniques used to create prototypes quickly and efficiently. From laser cutting to custom molded silicone, the main aim of RP is to allow designers and engineers to test out their ideas before committing to full-scale production. This can save time and money in the long run, as any design flaws can be ironed out at the prototype stage.

There are several techniques available when it comes to rapid prototyping – each has its own advantages and limitations.

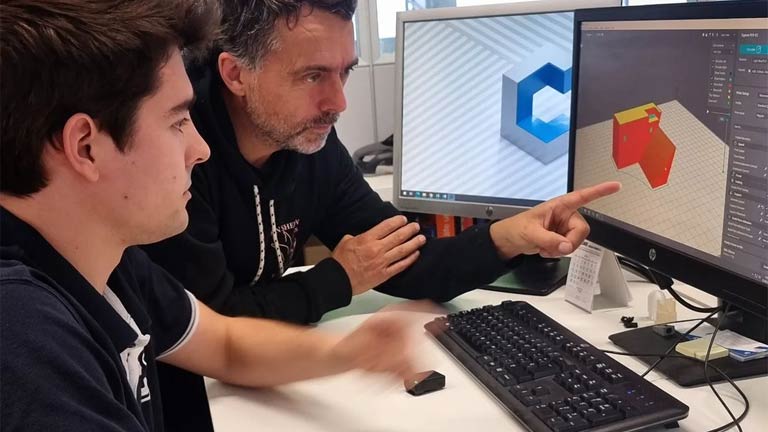

3D Printing

3D printing is the opposite of subtractive manufacturing which involves the removal of materials to create an object. There is a mixture of technologies that can be used for this particular prototyping technique, each with its own set of advantages and limitations. The most common technology used for consumer-grade 3D printers is fused filament fabrication (FFF), which melts and extrudes filaments of plastic to build up an object layer by layer. Stereolithography (SLA), selective laser sintering (SLS), and Direct Metal Laser Sintering (DMLS) are other examples of technologies available.

It’s imperative to assess the strengths and weaknesses of each technology so that you can choose the right one for your project. FFF is the most versatile technology and can be used to produce a wide range of objects with different properties. SLA offers high accuracy and detail resolution, making it ideal for small, intricate parts. SLS is well-suited for large-scale objects or those with complex geometries, while DMLS is ideal for metal parts with intricate designs.

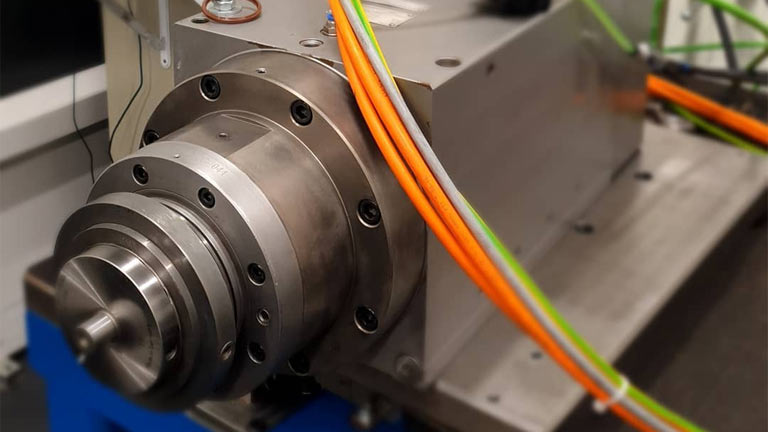

CNC Machining

CNC machining is a popular form of rapid prototyping and for good reason. It offers high accuracy and repeatability, as well as the ability to produce complex shapes. But it’s not the only option available, so how do you know if CNC machining is right for your project?

There are several things to consider when choosing a rapid prototyping technique, including build speed, accuracy, material options, and post-processing.

You should consider the following to help you decide if CNC specifically is right for you:

Build Speed: CNC machining is generally faster than other forms of 3D printing, but slower than other methods such as stereolithography (SLA) or selective laser sintering (SLS).

Accuracy: CNC machining can achieve very high levels of accuracy, making it a good choice for parts that require tight tolerances.

Material Options: CNC machining allows you to work with a wide variety of materials, including plastics, metals, and composites. This makes it a versatile option for many different types of projects.

Post-Processing: CNC machined parts often require little or no post-processing, which can save time and money.

Laser Cutting

Laser cutting is a form of rapid prototyping that uses a high-powered laser beam to cut the material into desired shapes and sizes. This technology has been around for decades and is commonly used in industrial applications such as cutting metals, plastics, and glass.

One of the benefits of laser cutting is its precision. Laser cutting can produce very intricate designs with a high degree of accuracy. Additionally, laser cutting is fast and relatively inexpensive compared to other forms of prototyping.

There are some drawbacks to laser cutting, however. First, the material being cut must be able to withstand the high temperatures generated by the laser beam. Second, because laser cutting produces heat, it can cause warping or melting of certain materials. Laser cutting is not well suited for large-scale projects due to the limited size of most lasers.

Identifying Which Technique Meets Your Project Requirements

It can be difficult to determine which prototyping technique will best meet the requirements of your project. To make an informed decision, consider the type of product or part you are building, material preferences, complexity level desired for your prototype, and overall budget constraints.

If you’re working on aesthetics more than functionality then SLA (Stereolithography) might be a good choice for printing smaller detailed parts while if durability is key, injection molding should definitely not be overlooked as an option.

Other important considerations include production speed required- smaller individual products may call for 3D printers like FDM technology while larger products will have better success using more industrial forms such as CNC machining which yields faster completion times.

Overall being well-informed about varying options is essential when picking out the right rapid prototyping technique. Always do some research and seek expert consultation when necessary so that you avoid making mistakes.

Conclusion

It is important to understand the various rapid prototyping techniques available and how they can support your product development journey. Comparing and contrasting each process will help you determine which technique best suits your unique project needs. By understanding the different features associated with each form of prototyping, you can achieve a successful end product that meets user demands from the initial design phase through to production.