3D printing is no longer a tool for creating simple, quick, and dirty prototypes. The industry has evolved a fair bit since its inception back in the 1980s. It’s now a legitimate manufacturing alternative that is already disrupting the industry and further creating new innovative business models.

Additive manufacturing (AM), as it’s technically called, has the potential to completely change the role of the supply chain in the economy. It may even get rid of it altogether. While it hasn’t yet reached mass adoption, the growth rate currently stands at approximately 12-13% per year. And the list of 3D-printable materials has doubled in the last 5 years.

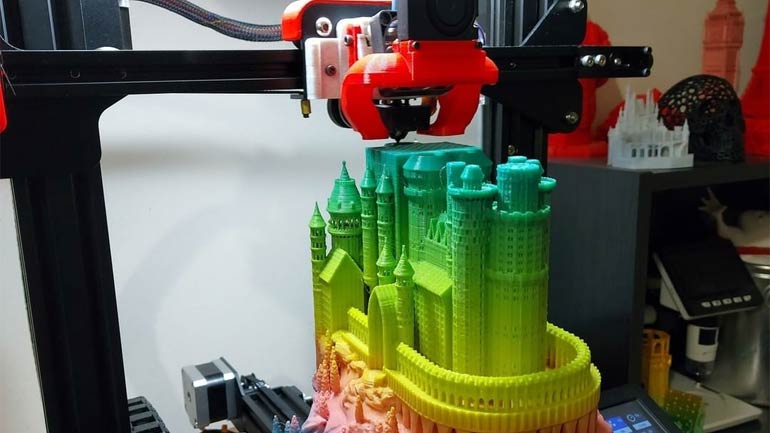

This may come as a surprise to most people, as many are familiar with 3D printing from impressive Facebook videos showing creators making things out of plastic, for example. But the fact is that metals may soon overtake plastics as the material of choice, and printers are now much faster and can handle far larger products in terms of cubic size and type.

The range of products you can make with a 3D printer is far-reaching, and a wide range of industries are currently implementing the technology for the end product, rather than just prototypes. These are the benefits that the AM industry offers across industries.

Small Businesses and Low Volume Production

3D printing is ideal for manufacturing products quickly and easily, without requiring a small business or entrepreneur to enter into a high volume and expensive contract. It gives companies the chance to test the water, so to speak, allowing them to figure out what would work in the existing market.

Low volume production using a 3D printer used to come bundled with a higher unit cost, where the requirement to test outweighed any cost considerations. However, this is no longer the case, with technological developments in the industry lowering costs on the whole. AM is now a viable alternative to traditional manufacturing when it comes to high volume production as well.

The fact that 3D printing opens up opportunities for smaller businesses cannot be understated, as it gives them the chance to compete with large multinationals. This is also a benefit for consumers, with monopolies more easily disrupted by competitors.

Medical Devices

The 3D manufacturing process also benefits certain specific industries more than most, such as those selling medical devices. AM has already been used extensively in the field, with patients benefiting from printed bone implants, for example. The precision that 3D printing offers ensures each patient receives an implant that has been specifically designed for them.

Also, medicine often requires quick and adaptive manufacturing, exactly that which AM offers. It allows companies to create custom models relatively simply and doing so in very low volumes. Think prosthetics for amputees, or 3D components to help patients with their rehabilitation following an accident.

The Construction Industry

Construction has much to gain from the growth of AM. It can be used in a wide range of applications, including extrusion, which includes cement or concrete, foam, and polymers. It can also be used for powder bonding as well as additive welding.

3D printing can be used across several sectors, with private, industrial, commercial, and public projects being able to benefit from the advantages this technology offers the production process: lower employee costs, far less waste, and improved functional integration. There is an excellent example of this in Yaroslav, Russia, where a 3D-driven production process led to the construction of an entire residential building.

Creative Industries (Art and Jewelry)

Perhaps an unexpected industry to benefit from the technology of 3D printing is the creative field, for example in the making of jewelry. It has allowed artists across the planet to deliver intricate pieces of jewelry at a low cost, while also providing unique designs with ease.

With consumers more aware than ever, the desire to obtain one-off pieces has increased in recent years. Artists operating on a small scale, for example on websites like Etsy, are now able to genuinely compete with traditional juggernauts in the industry. Individual artists like Oliver van Herpt and Gilles Azzaro, for instance, are enjoying a significant rise in demand despite working in small studios.

Advantages of Localized Production

3D printing helps in the decentralization of the manufacturing process. This benefit is undoubtedly more important than ever, with supply chains being severely disrupted by Covid-19 and the accompanying lockdowns. Countries are attempting to lower their dependencies, particularly if transport costs are lowered.

In addition, localized production also leads to a reduction in an individual company’s environmental impact. Considering governments are beginning to impose restrictions on CO2 emissions, AM is a viable way to improve green efficiency.

What Will the Future Look Like?

We’re still a way of establishing the effects of AM on the wider economy. But there’s no doubt that the technology will take a larger chunk of the manufacturing industry, the question is by just how much.

The answer may lie in the development of robotics, where a combination of the two industries would result in a far more agile and productive manufacturing process. The economic effects of such a combination would certainly be significant.