As the saying goes, “Seeing is believing.” When it comes to packaging design, this rings particularly true. Without a tangible example of what your product’s packaging could look like, it can be difficult to communicate with stakeholders and make informed decisions about design direction. That’s where prototyping comes in – creating physical or digital models of your packaging can help you test different ideas, gather feedback from customers, and ultimately create a final product that meets everyone’s needs. We will look to explore here just why prototyping is crucial for businesses looking to improve their packaging designs and how it can benefit your bottom line.

Benefits of Prototyping for Businesses

There are many benefits that businesses can gain from prototyping their packaging designs. Perhaps the most obvious benefit is that it allows businesses to see what their packaging will look like before investing in the production of large quantities. This can save businesses from incurring significant expenses if they find that their original design doesn’t work well or needs to be revised.

In addition, mockups of packaging will allow businesses to test out different packaging materials and methods to see which ones work best for their products. This can be particularly important for delicate items or products that need to be shipped long distances. By testing out different packaging options, businesses can ensure that their products will arrive at their destination safely and in good condition.

Prototyping also provides businesses with an opportunity to get feedback on their packaging designs from potential customers. This feedback can be invaluable in helping businesses improve the overall look and functionality of their packaging. Additionally, it can help businesses make sure that their packaging accurately reflects the branding and image that they want to project to the world.

The Process of Creating a Prototype

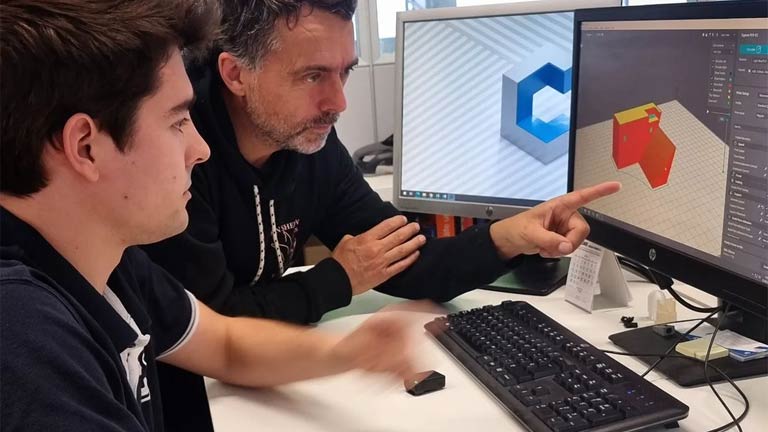

There are several steps involved in creating a prototype. The process will begin with a product idea. Once you have an idea, you need to sketch it out or create a 3D model. Next, you will need to create a mold or form for your prototype.

This can be done with CAD software or by hand. You will need to create the actual prototype. This can be done with 3D printing or other methods.

Cost and Time Considerations

Prototyping can be a costly and time-consuming endeavor but the benefits far outweigh the costs and time considerations.

When it comes to developing packaging for a new product, prototyping is essential. By creating prototypes of your packaging, you can test out different designs and materials to find the perfect combination for your product. Prototyping also allows you to assess the manufacturing process and make any necessary adjustments before committing to large-scale production.

It can take varying amounts of time to produce a prototype depending on the complexity of the design that businesses are looking for when it comes to obtaining the ultimate protection and maintaining brand identity. However, even a simple prototype can cost several hundred dollars to produce. And if you need multiple prototypes to test out different design options, the cost can quickly add up.

It can take several days to many weeks to create an effective prototype, depending on how complicated it is to produce. So, it’s important to factor in the lead time when planning your product launch timeline.

Despite the costs and time considerations, prototyping is an essential step in developing successful custom packaging for your product. By taking the time to create prototypes, you can ensure that your packaging is well-designed, functional, and ready for mass production.

What to Do if the First Prototype Isn’t Right

If your first prototype isn’t right, don’t despair! Here are some things you can do to improve it:

- Talk to the people who will be using the packaging. Find out what they think of the design and what would make it better for them.

- Make sure all the dimensions are correct. Measure everything carefully and make adjustments as necessary.

- Check that the materials you’ve chosen are durable and fit for purpose. Make sure they’re up to scratch before you move on to mass production.

- Consider how easy or difficult the packaging is to assemble. Can it be improved?

It is well worth spending time producing a good prototype because ultimately it can save a company money. The risk of getting the packaging wrong is not worth taking.

Conclusion

Prototyping is an essential part of the packaging design process, and it can be beneficial for businesses in many ways. It allows them to test consumer reactions to their upcoming product and get feedback from potential customers before investing too much time and money into a design that may not work. Ultimately, prototyping helps companies save time and resources while also creating more impactful final products with improved customer experiences. The importance of prototyping when designing packaging cannot be overstated; if you want your business to succeed, you need to consider making prototypes of your designs before launching them on the market.