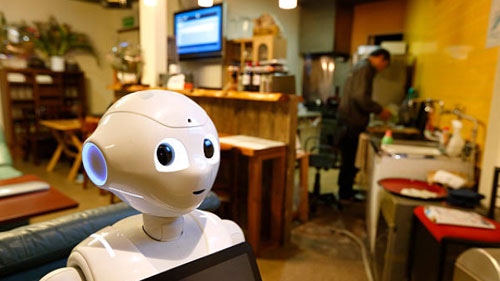

As the automation industry evolves, some have grown concerned that robotics would lead to people being laid off in the manufacturing sector. Their concerns are not unfounded. Compared to human employees, robotics don’t need to clock out or request lunch breaks. They can perform at their highest efficiency around the clock, repeating the same tasks with consistent speed and quality. That’s why machines have grown popular in automation. However, robotics lack human thinking which is a vital component for successful manufacturers. When paired together though, humans and robots can create a smooth and efficient environment.

To take the best of robots and humans, the technology sector has come up with with a new solution: collaborative robotics. Built with machine learning capabilities and cutting-edge artificial intelligence, these types of robots are more efficient coworkers to their human counterparts than previous predecessors. What sets them apart is their ability to be “taught” to execute smaller-scale tasks than a standard industrial robot arm. Cobots can then work and interact with individuals in the warehouse, making it less stressful and easier on a factory’s human employees.

Collaborative robotics has already grown in popularity among manufacturers, and it’s only expected to increase in number over the next few years. A study recently done by experts has estimated that by the end of the 2020s, there will be over 40,000 cobots in distribution centers, warehouses and other industrial businesses. To understand and learn more about cobots and what they can do, take a look at the infographic below for more information.

Infographic provided by Productive Robotics